24LC512-I/SM Common troubleshooting and solutions

Introduction to 24LC512-I/SM and Common Issues

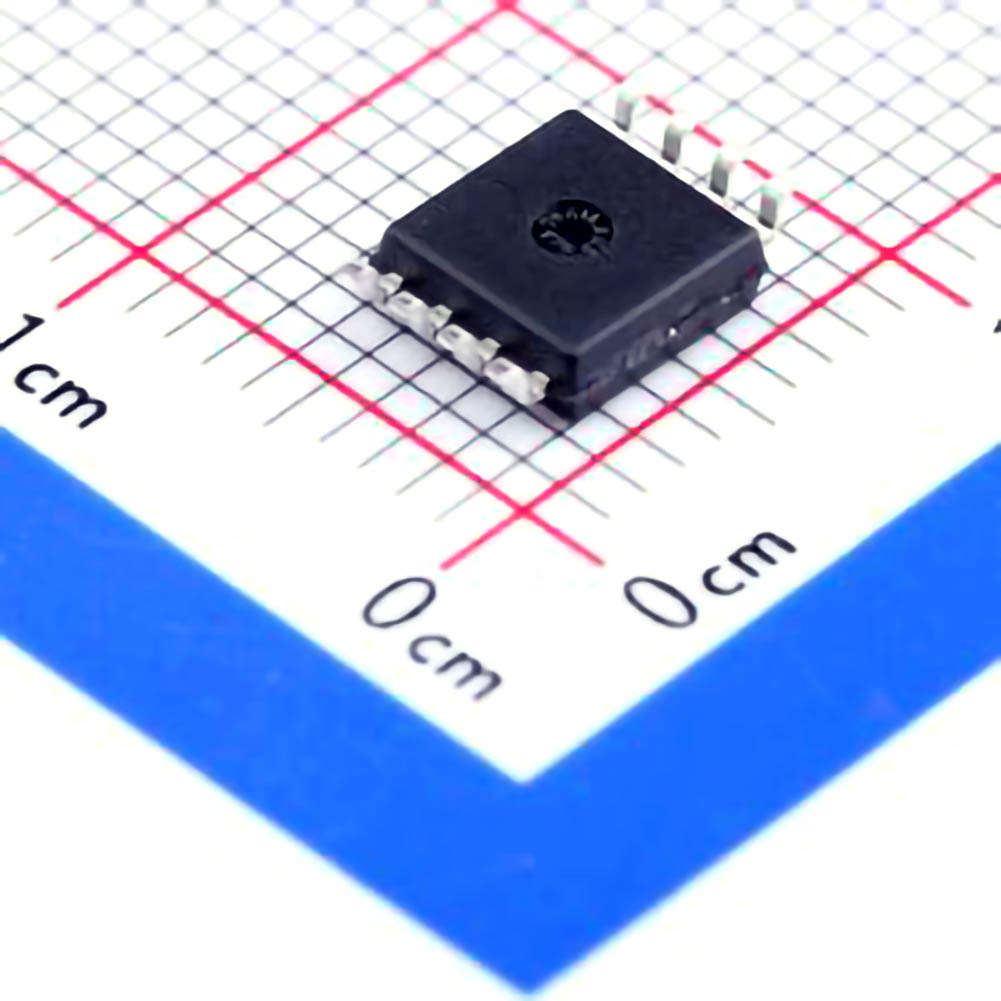

The MICROCHIP 24LC512-I/SM is a popular 512K-bit (64K-byte) I2C-compatible EEPROM memory chip designed for various applications, from consumer electronics to industrial systems. Known for its reliability and low Power consumption, it’s a favored choice for storing non-volatile data. However, like any electronic component, the 24LC512-I/SM can sometimes experience issues that affect its performance. These issues can range from simple Communication errors to more complex data corruption scenarios.

Understanding the most common problems and troubleshooting steps is essential for engineers, hobbyists, and technicians working with this component. In this article, we will explore some of the typical issues you might encounter with the 24LC512-I/SM and provide detailed solutions to help you resolve them efficiently.

1. Communication Failures

One of the most frequent problems users encounter with the 24LC512-I/SM is communication failure. This issue typically arises when the EEPROM doesn’t properly interact with the microcontroller or other I2C master devices.

Possible Causes:

Incorrect I2C address: The 24LC512-I/SM uses a 7-bit I2C address, and if the address is not correctly set, communication will fail.

SDA/SCL lines not properly connected: If the data (SDA) or clock (SCL) lines are not properly wired or there’s a poor connection, the EEPROM cannot communicate with the master device.

Incorrect I2C bus speed: The EEPROM operates with I2C speeds up to 400kHz. If the master device is set to a higher speed than the EEPROM can handle, communication failure can occur.

Power supply issues: A weak or unstable power supply can cause intermittent communication failures.

Troubleshooting Tips:

Verify the I2C address: The 24LC512-I/SM can have different address configurations depending on how the A0, A1, and A2 pins are connected. Double-check these settings and make sure the address you’re using matches the physical configuration of the EEPROM.

Inspect wiring: Ensure that the SDA and SCL lines are correctly connected between the EEPROM and the microcontroller. Use a multimeter or oscilloscope to check the integrity of the connections.

Check pull-up resistors: I2C communication requires pull-up resistors on both the SDA and SCL lines. Typically, 4.7kΩ resistors are used, but this can vary depending on the bus configuration. Ensure that these resistors are present and properly connected.

Test the I2C speed: Make sure that the I2C clock speed on your master device is set to a level that is compatible with the EEPROM. If necessary, try lowering the clock speed to 100kHz to ensure compatibility.

2. Data Corruption or Loss

Another common issue with the 24LC512-I/SM is data corruption or unexpected data loss. This issue can be frustrating, especially when the EEPROM is used to store critical data that needs to be preserved even during power-down events.

Possible Causes:

Power failure during write operation: If the power supply is interrupted while the EEPROM is in the process of writing data, the data in the memory can become corrupted.

Write operation errors: Incomplete or faulty write operations, often caused by improper I2C commands or communication timeouts, can lead to corrupted data.

Overwriting memory: The 24LC512-I/SM allows data to be written to specific memory locations. However, if an incorrect address is used, data may be overwritten unintentionally, leading to data loss.

Physical damage: Though rare, physical damage to the chip or the PCB could cause read/write issues, leading to corrupted data storage.

Troubleshooting Tips:

Use a capacitor for power stability: To prevent power loss during critical write operations, consider adding a small capacitor (e.g., 10μF) near the power supply pins of the EEPROM to maintain stability during power-down events.

Confirm write completion: The 24LC512-I/SM has an internal write cycle that takes a certain amount of time (typically 5ms per byte). Ensure that your code waits for the write cycle to complete before issuing a new command.

Implement error-checking protocols: When reading and writing data, consider using checksums or CRC (Cyclic Redundancy Check) to verify that the data has been written correctly. This helps identify corruption and recover data if needed.

Test with a new EEPROM: If data corruption persists despite troubleshooting, the EEPROM chip itself may be defective. Replacing it with a new 24LC512-I/SM can sometimes resolve the issue.

3. Slow Data Access

Users sometimes report slower-than-expected data access times when working with the 24LC512-I/SM. Since the EEPROM operates via the I2C protocol, certain factors can influence the speed at which data can be read or written.

Possible Causes:

High I2C bus traffic: If the I2C bus is shared with multiple devices, high traffic or congestion can slow down communication with the EEPROM.

Low clock speed: The I2C clock speed may be set too low, leading to slower data transfer.

Overloaded microcontroller: If the microcontroller is managing too many tasks simultaneously, it may struggle to maintain high-speed communication with the EEPROM.

Troubleshooting Tips:

Optimize the I2C bus: If the EEPROM shares the bus with other devices, try isolating it or optimizing the communication pattern to reduce traffic and avoid congestion.

Increase the I2C clock speed: If possible, increase the clock speed of the I2C bus, but make sure the EEPROM can handle the increased speed.

Check the microcontroller load: Ensure that the microcontroller has sufficient processing power to handle the I2C communication without being overloaded by other tasks.

Advanced Troubleshooting and Solutions

While the previous section covered basic troubleshooting, some issues may require more in-depth analysis. This section delves into advanced troubleshooting techniques and solutions for addressing persistent or complex problems with the 24LC512-I/SM EEPROM.

4. Write-Protect Pin Issues

The WP (Write Protect) pin on the 24LC512-I/SM allows for disabling or enabling write operations. If the WP pin is inadvertently connected to ground or left floating, it may prevent the EEPROM from accepting write commands.

Possible Causes:

WP pin is grounded: When the WP pin is connected to ground, the chip enters write protection mode, and no data can be written to the EEPROM.

Floating WP pin: A floating WP pin can lead to unreliable behavior, with the EEPROM sometimes preventing writes without any clear indication.

Troubleshooting Tips:

Ensure the WP pin is properly configured: If you require the ability to write to the EEPROM, make sure the WP pin is either tied to VCC (logic high) or left unconnected (floating). If you want to disable write access for protection, tie it to ground.

Use a pull-up resistor: If you choose to leave the WP pin unconnected, a pull-up resistor (e.g., 10kΩ) to VCC can help stabilize the pin and prevent erratic behavior.

5. Addressing Alignment Issues

When using the 24LC512-I/SM to store large amounts of data, ensuring that the data is correctly aligned and accessed is essential for reliable performance. Misaligned read or write operations can lead to incomplete or corrupted data.

Possible Causes:

Improper address alignment: The EEPROM’s internal memory is divided into pages. Each page is typically 128 bytes, and if data is written across page boundaries without proper handling, some of it may not be written correctly.

Inconsistent data size: If the data being written doesn’t align with the page structure, some bytes may not be written or read correctly, leading to data corruption.

Troubleshooting Tips:

Manage page boundaries: Ensure that when writing or reading data, the operations respect the page boundaries. If you need to write more than 128 bytes, break the data into smaller chunks that fit within a page.

Use block write and read operations: The 24LC512-I/SM supports block write and block read commands, which allow for more efficient and aligned data access.

6. Temperature and Environmental Factors

Environmental factors, such as temperature extremes or excessive moisture, can affect the reliability of the 24LC512-I/SM. Although this chip is designed for general-purpose use, it may experience issues in harsh environments.

Possible Causes:

Excessive temperature: High or low temperatures can cause the chip to malfunction, leading to data corruption or loss of communication.

Moisture or humidity: Water or high humidity levels can cause short circuits or corrosion that affects the functionality of the EEPROM.

Troubleshooting Tips:

Ensure proper environmental conditions: If the chip is being used in an environment with extreme temperatures or humidity, ensure that it is adequately protected. Consider using a protective coating or housing to shield the EEPROM.

Monitor the chip’s temperature: If possible, use thermal sensors to monitor the temperature around the EEPROM. Ensure that it stays within the recommended operating range (typically 0°C to 70°C).

7. Electromagnetic Interference ( EMI )

Electromagnetic interference (EMI) from nearby components or external sources can disrupt communication with the EEPROM, especially when the I2C bus is not properly shielded.

Possible Causes:

Poor PCB layout: If the SDA and SCL lines are too long or improperly routed, they can act as antenna s and pick up interference.

High-frequency noise: External devices emitting high-frequency electromagnetic radiation can interfere with the I2C signals.

Troubleshooting Tips:

Optimize PCB layout: Minimize the length of the SDA and SCL traces and keep them well separated from noisy components.

Use shielding: If EMI is suspected, consider adding shielding around the EEPROM and the I2C lines to block external noise.

In conclusion, the 24LC512-I/SM is a reliable and versatile EEPROM chip that can serve a wide range of applications. By understanding common troubleshooting techniques and applying the solutions outlined in this guide, you can ensure that your EEPROM works smoothly and efficiently. Whether it’s addressing communication failures, data corruption, or environmental factors, the key to successful troubleshooting lies in a systematic and thorough approach to problem-solving.

If you're looking for models of commonly used electronic components or more information about 24LC512-I/SM datasheets, compile all your procurement and CAD information in one place.

( Partnering with an electronic component supplier) sets your team up for success, ensuring that the design, production and procurement processes are streamlined and error-free. (Contact us) for free today.