TPS61230DRCR Common troubleshooting and solutions

Understanding the TPS61230DRCR and Common Troubleshooting Issues

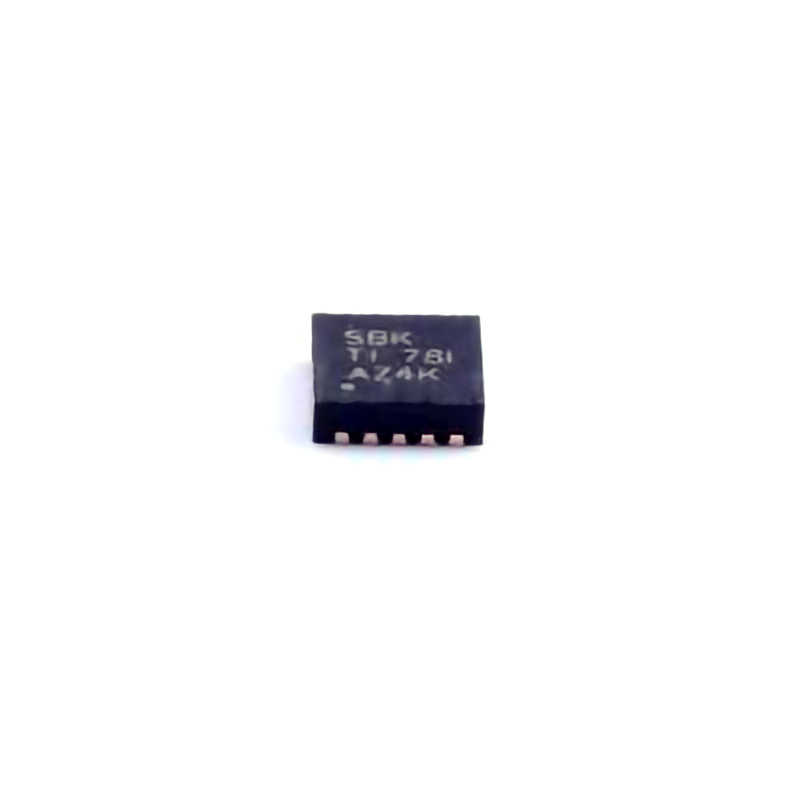

The Texas Instruments TPS61230DRCR is a high-efficiency, small, and versatile step-up converter, designed to convert low input voltages into higher, stable output voltages. Commonly used in battery- Power ed devices and portable applications, it helps to extend the battery life while providing the necessary power for circuits requiring higher voltage levels. Despite its popularity and reliability, like all electronic components, the TPS61230DRCR can sometimes present issues in specific applications or designs.

In this part of the article, we will explore the typical problems encountered when using the TPS61230DRCR, and provide an overview of how to diagnose and resolve these issues. Let’s dive into the most common troubleshooting areas.

1. Inconsistent Output Voltage

One of the most common issues that designers encounter with the TPS61230DRCR is an unstable or inconsistent output voltage. This issue could arise from various factors, and diagnosing the root cause requires careful inspection of the design and the circuit.

Possible Causes:

Incorrect Feedback Resistor Selection: The feedback network plays a crucial role in regulating the output voltage. If the resistors are improperly chosen or if their values are incorrect, the feedback loop could be miscalibrated, leading to an unstable or incorrect output voltage.

Faulty capacitor s: Inadequate or malfunctioning input or output Capacitors can introduce noise or instability into the converter’s operation, causing fluctuations in the output voltage.

Inductor Issues: The inductor used in the step-up converter is another critical component. If the inductor’s value is too low or its quality is poor, it can lead to a weak or unstable output.

Solutions:

Check Resistor Values: Ensure the resistors in the feedback network are of the correct value as per the design guidelines in the TPS61230DRCR datasheet. Double-check their tolerance to avoid inaccuracies.

Use Recommended Capacitors: Always use capacitors with values that meet the manufacturer’s recommendations. Check for any signs of aging or damage, as capacitors degrade over time, which could affect their performance.

Verify Inductor Selection: Use the recommended inductor values specified in the datasheet to ensure optimal performance. Test the inductance with an LCR meter to confirm its specifications.

2. Overheating of the TPS61230DRCR

Overheating is a common problem, especially when the converter is under heavy load or if it operates in high-temperature environments. Prolonged overheating can damage the device and cause it to shut down or fail prematurely.

Possible Causes:

Excessive Output Current: Drawing too much current from the output can overload the converter and cause it to heat up. This could be due to either a heavy load or a design flaw in the system.

Inadequate Heat Dissipation: If the PCB layout does not allow for sufficient heat dissipation, the converter will struggle to maintain optimal performance. The lack of proper thermal vias or an inadequate copper area for heat sinking can exacerbate this issue.

Solutions:

Verify Load Requirements: Make sure that the output current demand does not exceed the rated current capacity of the TPS61230DRCR. The datasheet provides maximum load specifications that should be followed to avoid overstressing the device.

Improve PCB Layout for Heat Dissipation: To reduce heat buildup, use a PCB layout that allows for adequate heat dissipation. This includes providing enough copper area for the ground and power traces and adding thermal vias to transfer heat to the back of the PCB.

3. Start-Up Failure

Another issue that users may face is the failure of the converter to start up properly. This problem could manifest as the converter not delivering power to the load or the device failing to enter the required operational state.

Possible Causes:

Insufficient Input Voltage: The TPS61230DRCR has a specific minimum input voltage requirement. If the input voltage is too low, the converter will fail to initiate. The input voltage should be above the minimum threshold for the converter to operate.

Component Faults: A malfunctioning component, such as a shorted or open component, can prevent the start-up sequence from initiating properly.

Solutions:

Check Input Voltage: Verify that the input voltage is within the specified range for the TPS61230DRCR to operate. For most configurations, the input voltage needs to be higher than the minimum startup voltage, which can be found in the datasheet.

Inspect Components for Faults: Carefully check the circuit components, including capacitors, resistors, and Inductors , for any signs of damage. A multimeter or oscilloscope can be useful to check for continuity and measure voltages at different points in the circuit.

4. Electromagnetic Interference ( EMI ) and Noise

Electromagnetic interference (EMI) can be a significant problem in circuits using switching regulators like the TPS61230DRCR. Noise and ripple can affect sensitive components in your system, leading to erratic behavior or failure.

Possible Causes:

Inadequate Filtering: If the output capacitor or input filter is insufficient or of poor quality, switching noise may not be adequately suppressed.

Improper Layout: A poor PCB layout can exacerbate EMI. If high-frequency switching signals are not well-shielded or properly routed, they can couple into nearby traces or components.

Solutions:

Enhance Filtering: Increase the output capacitor size or add additional filtering capacitors to smooth out the voltage ripple. Use low ESR (Equivalent Series Resistance ) capacitors to improve the filtering performance.

Improve PCB Layout: Ensure that high-current traces are kept short and thick to minimize resistance and inductance. Shield sensitive areas of the circuit and consider using ground planes to reduce EMI. Place inductors and capacitors close to the switching node to minimize noise propagation.

5. Reduced Efficiency

Low efficiency in power converters results in unnecessary energy loss, which can manifest as heat generation and poor performance. Efficiency issues with the TPS61230DRCR can often arise from incorrect component choices or poor layout practices.

Possible Causes:

Incorrect Inductor: An inductor with an incorrect value or poor quality can contribute to efficiency loss. Inductors with higher core losses or higher resistance increase the energy dissipation.

Suboptimal Component Selection: Choosing capacitors or diodes with suboptimal characteristics can reduce efficiency.

Poor PCB Layout: Inefficient routing of power traces or improper placement of components can cause additional resistance and inductance, reducing overall efficiency.

Solutions:

Select the Right Inductor: Choose an inductor with low resistance and low core losses that matches the recommended specifications for the TPS61230DRCR.

Use High-Quality Components: Use low ESR capacitors and Schottky diodes to minimize energy losses.

Optimize PCB Layout: Ensure that power traces are short, thick, and low in resistance. Optimize the placement of components to minimize parasitic inductances and resistances.

Advanced Troubleshooting and Solution Strategies for the TPS61230DRCR

Now that we've covered the fundamental issues commonly encountered with the TPS61230DRCR, it's time to explore more advanced troubleshooting techniques and solutions. This section will focus on additional, less obvious problems that may arise, and how to solve them efficiently.

1. Undervoltage Lockout (UVLO) Issues

Undervoltage lockout (UVLO) is a safety feature built into the TPS61230DRCR to prevent it from operating at voltages below a certain threshold. While UVLO protects the device from damage, it can sometimes trigger erroneously in circuits with unstable or fluctuating input voltage.

Possible Causes:

Fluctuating Input Voltage: An unstable or noisy input voltage that dips below the UVLO threshold may cause the converter to turn off repeatedly.

External Factors: External environmental factors such as temperature extremes or poor connections in the input power supply can lead to input voltage fluctuations.

Solutions:

Check for Stable Input Voltage: Monitor the input voltage to ensure it stays within the recommended operating range. Use a multimeter or oscilloscope to check for voltage dips that might trigger UVLO.

Improve Input Power Quality: Use decoupling capacitors or low-pass filters to stabilize the input power. Also, consider using a more stable power source or regulator to avoid voltage dips.

2. Output Voltage Ripple

While some ripple is inherent in switching regulators, excessive ripple can indicate a problem that needs to be addressed. High ripple levels can negatively affect sensitive components in your circuit, leading to malfunction or failure.

Possible Causes:

Low-Quality Output Capacitors: Capacitors with high ESR can fail to filter high-frequency noise properly, leading to excessive ripple.

Improper Feedback Control: An issue in the feedback loop, such as incorrect resistor values, can lead to improper regulation, causing ripple.

Solutions:

Use Low-ESR Capacitors: Choose high-quality output capacitors with low ESR for effective filtering. Capacitors with ceramic materials are often ideal for minimizing ripple.

Check Feedback Loop Stability: Ensure the feedback resistors are correctly chosen and that the loop is stable. Use a scope to check for irregularities in the feedback signal and adjust the feedback network as needed.

3. Device Protection Features (Thermal Shutdown)

The TPS61230DRCR comes equipped with built-in protection features like thermal shutdown and current limiting to prevent damage in the event of faults. While these features are beneficial, they can cause the device to shut down or operate unpredictably if not managed properly.

Possible Causes:

Overload Conditions: Drawing too much current or operating at high temperatures may trigger the thermal shutdown or current limit protection.

Inadequate Thermal Management : Poor heat sinking or insufficient ventilation can lead to overheating, causing the converter to shut down.

Solutions:

Optimize Current Draw: Ensure the load current is within the recommended limits. If the load requires more power, consider using a higher-rated converter or parallel converters.

Improve Thermal Management : Provide proper heat dissipation through the use of heat sinks, adequate copper areas, and thermal vias in the PCB layout.

Conclusion

Troubleshooting the TPS61230DRCR involves understanding both the component-specific issues and the broader system-level concerns that can affect its performance. By following the solutions outlined above and carefully checking component choices, PCB layout, and operating conditions, you can resolve common issues efficiently and ensure that your step-up converter operates at peak performance.

If you're looking for models of commonly used electronic components or more information about TPS61230DRCR datasheets, compile all your procurement and CAD information in one place.

(Partnering with an electronic component supplier) sets your team up for success, ensuring that the design, production and procurement processes are streamlined and error-free. (Contact us) for free today